Mechanical Engineering

Capstone

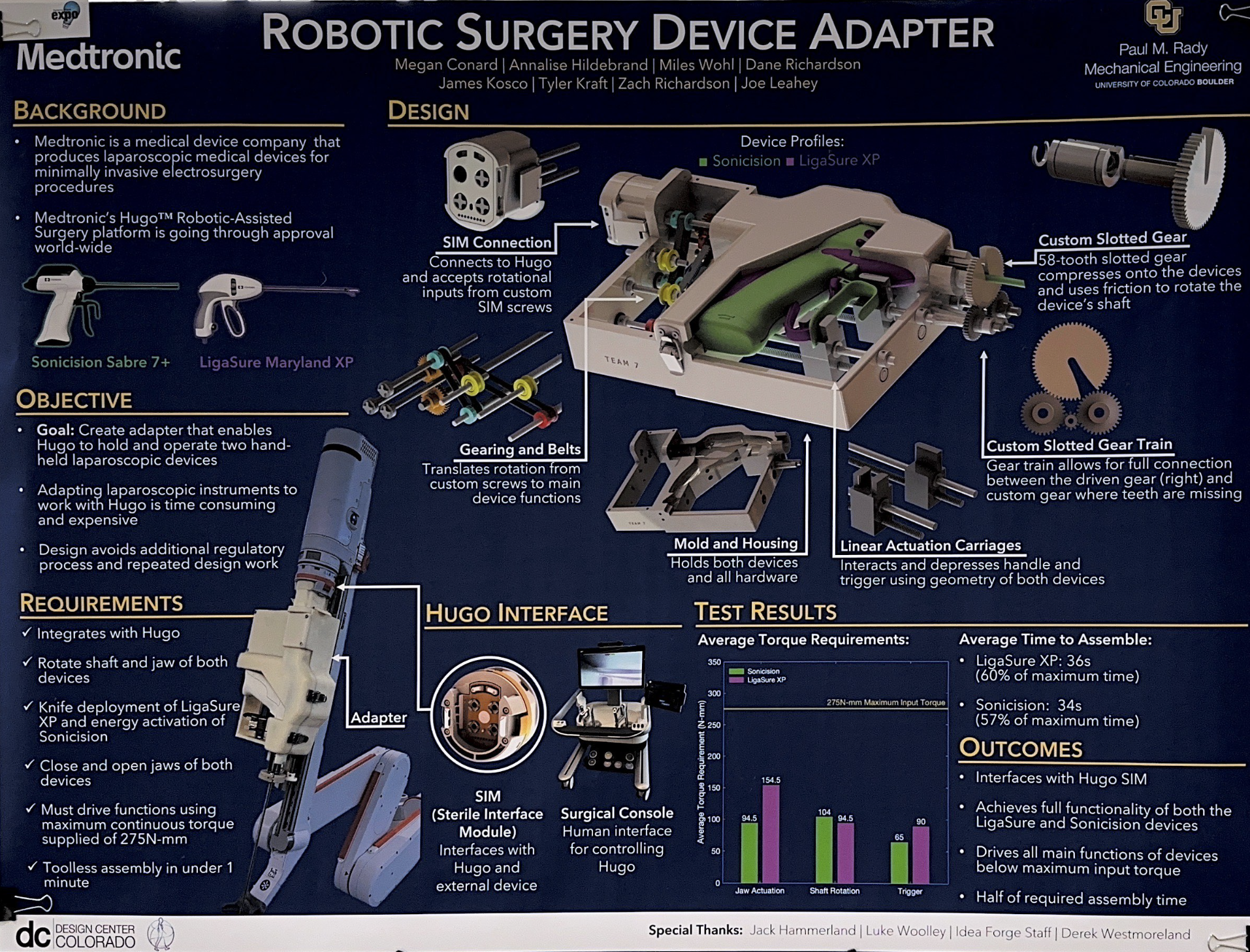

Medtronic Robotic Surgery Device Adapter

Exploratory project into developing mechanically driven solutions to hold human ergonomic tools in robotic applications, made possible by Medtronic. Our patent pending design adapts the Hugo Robottic Surgical Arm interface to pre-existing hand-held laproscopic surgical instruments.

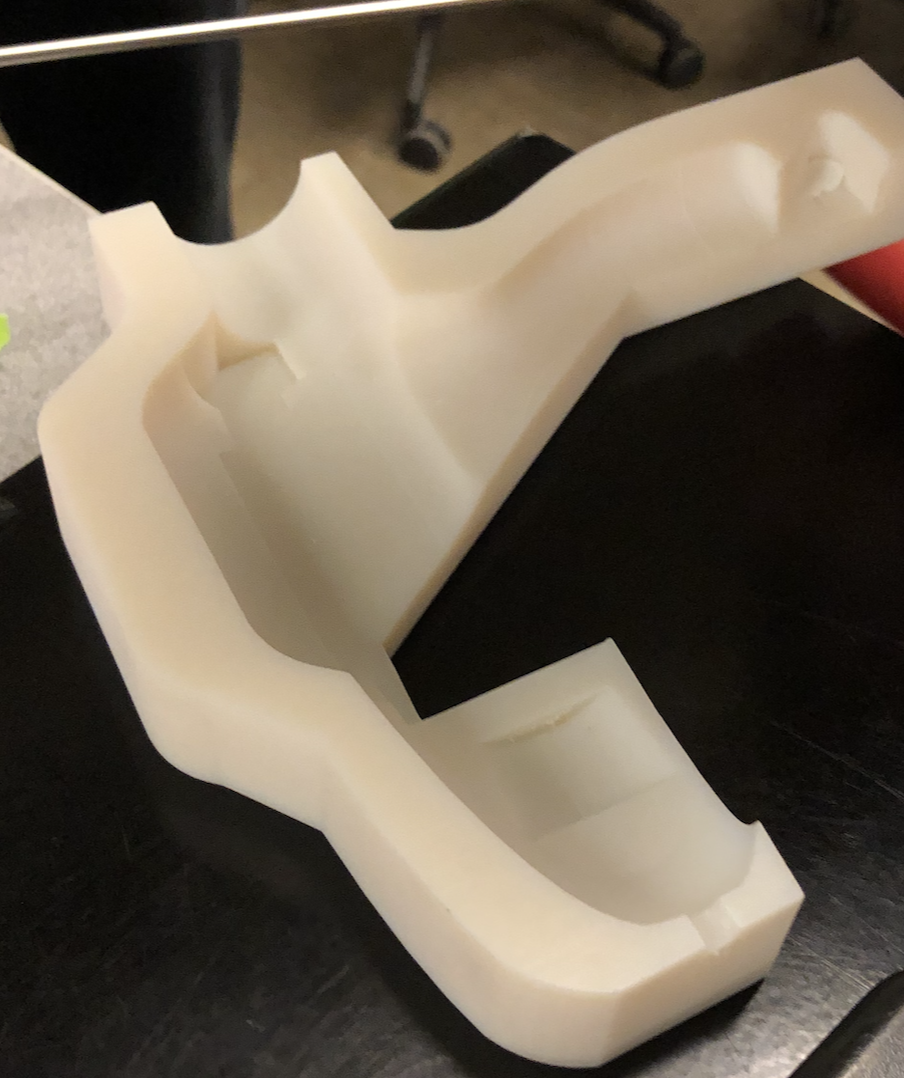

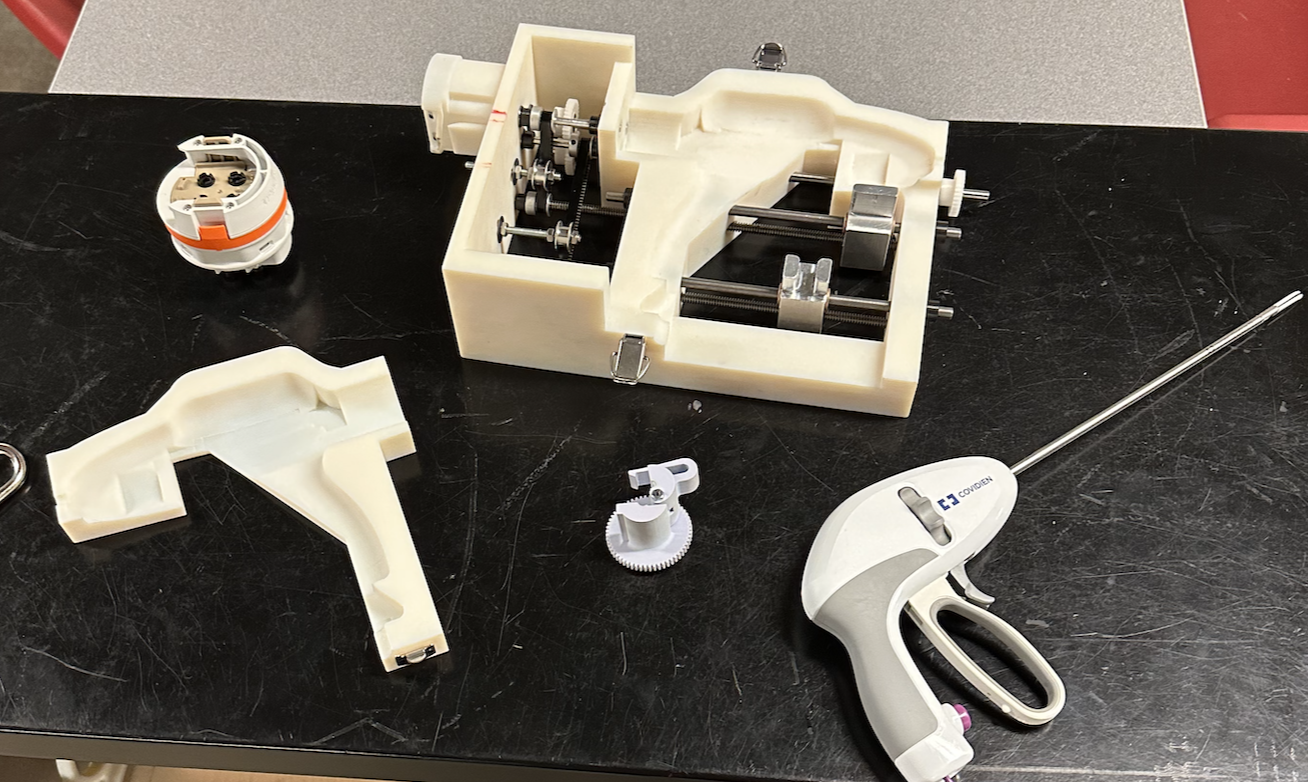

By overlaying digital renderings of the two desired surgical instrumemnts, keeping their shafts concentric at the base and tip, we were able to develop a 'tool-box' like design in which we cut out deep and shallow reliefs to hold each device at separate times. The thicker device has a deeper relief cut into the molded housing, allowing for the device to be held in place keeping the shaft in position. The thinner device needed a shallower cut out of the same space as the larger device, allowing for a secondary position to be carved from the mold to hold the device in place and keep its shaft in position. Mold bottom and mold lid are pictured above. These molds were manufactured through additive layering techniques on a PolyJet printter.

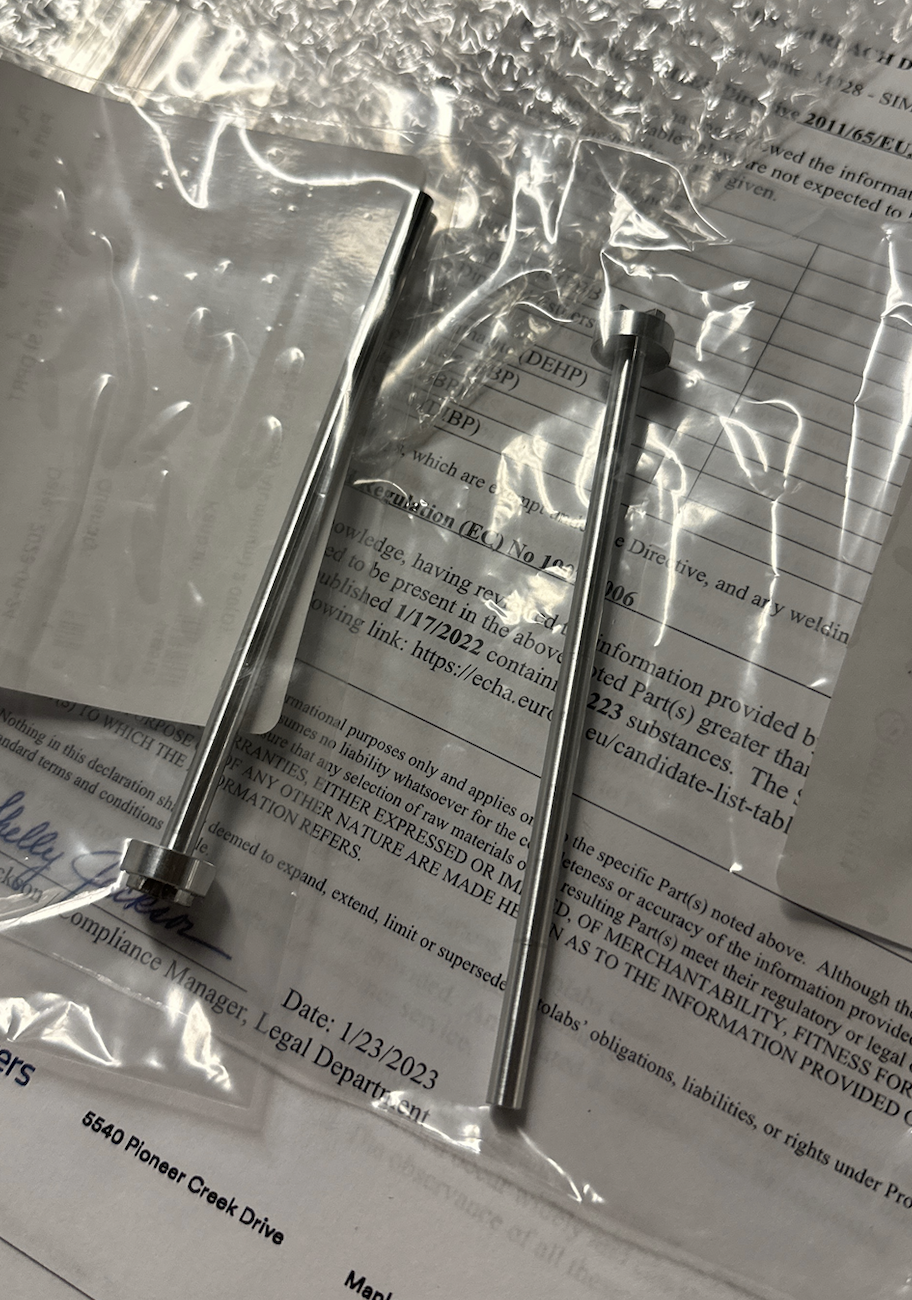

To utilize the rotational input (of 275 Nmm) from the Hugo arm SIM connection (Sterile Interface Module), our team designed and commissioned custom SIM Shafts - pictured above. These shafts are made from aluminum - material chosen due to its machinability given complex '+' head-shapes, and internal strength great enough to ranslate required forces.

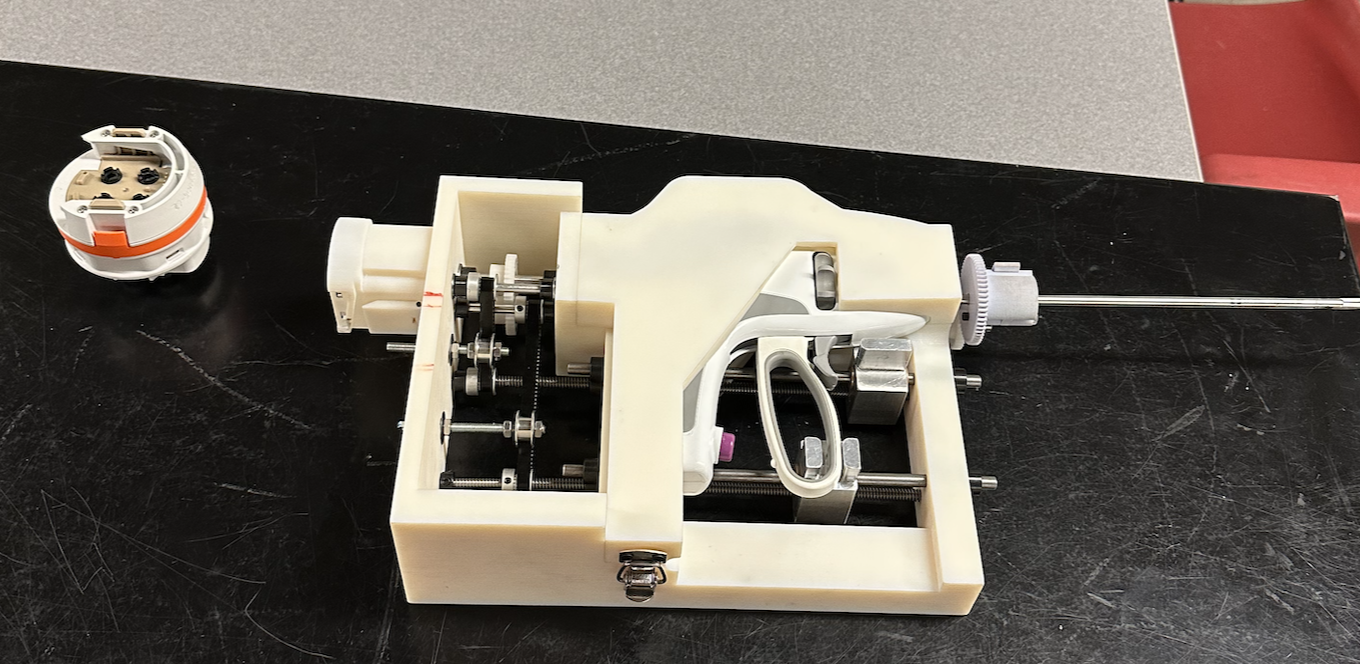

To translate rotational input to device actuation, we chose to use threaded steel lead-screws, standard off-the-shelf part, and a custom designed and manufactureed aluminum carriages that can move linearly along tthe screws and a sett of guide rods to depress the corresponding triggers and levers. The material choice again was due to aluminum's machinability and internal strengths sufficient for this application. The jaw-acttuatioin carriage in paricular was designed to be able to both push the lever closed and pull the lever open - should it become stuck in operation.

In positioning each of the desired outputs with the given inputs, our team chose to use a mix of gear-to-gear and gear-to-belt drive-trains to effectively translate rotational iniput to rotational and linear outputs. The final assembly can be seen above.