Freshman

Project

Background/ Client Info:

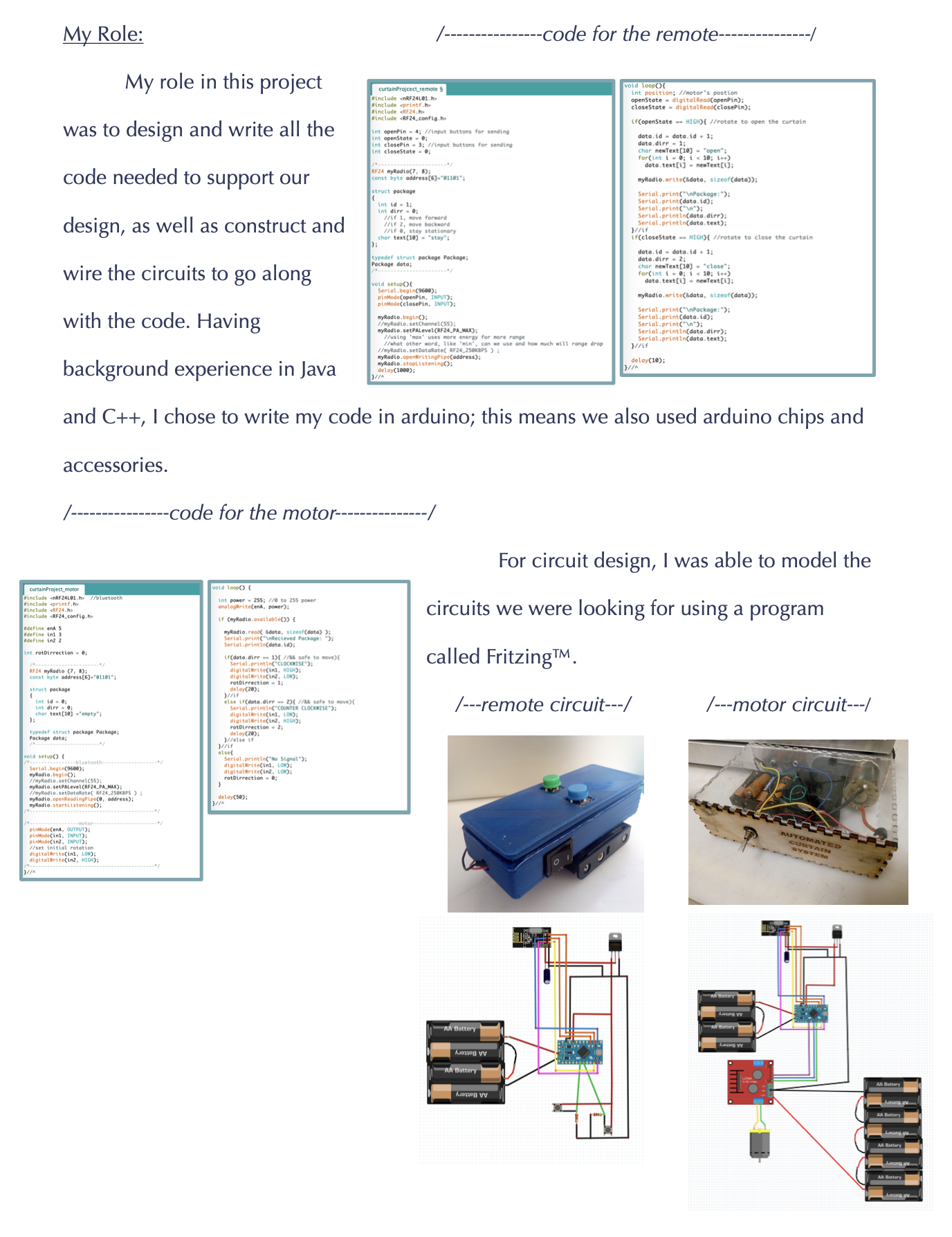

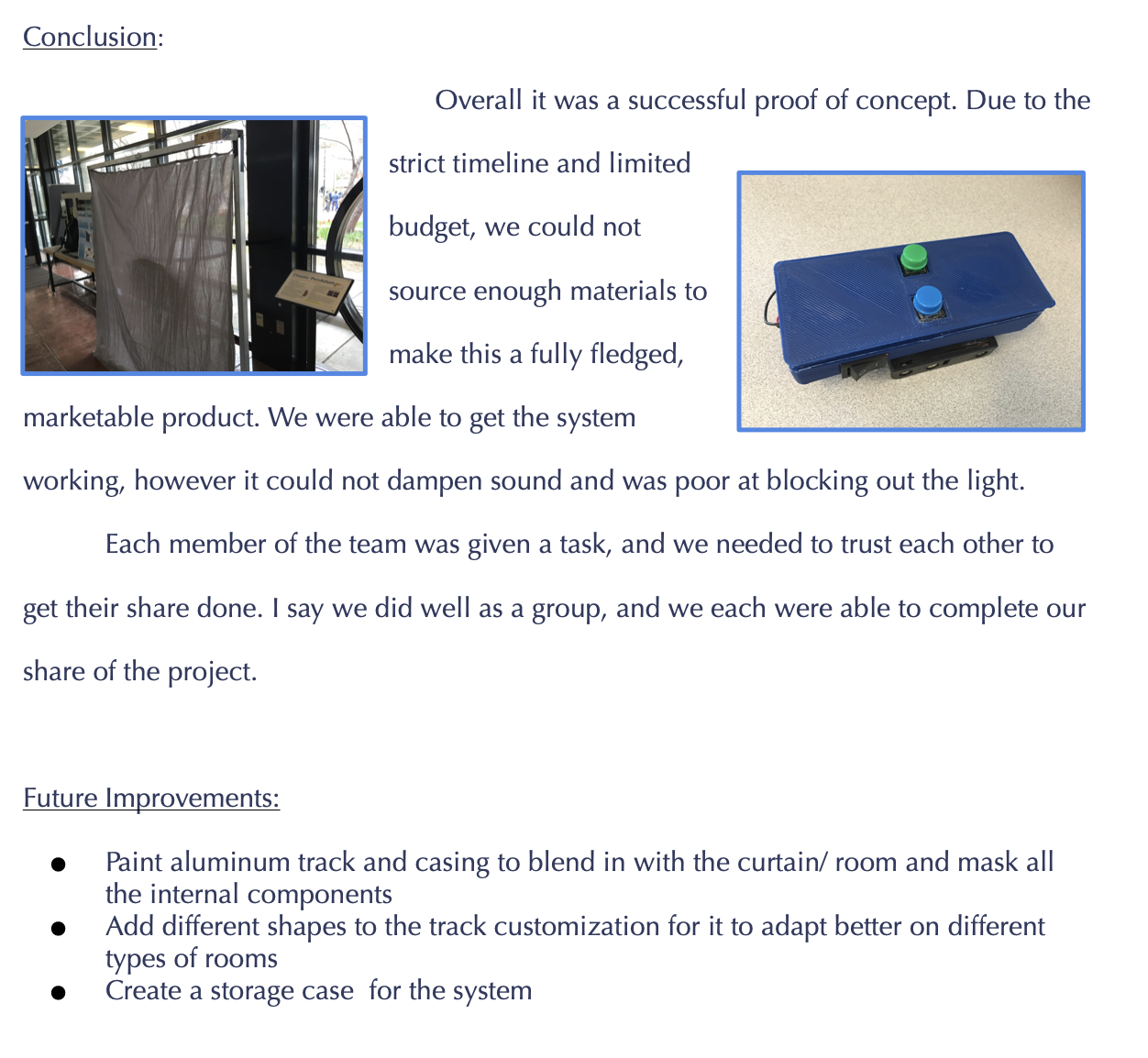

My team and I identified what we believed to be a common issue amongst college students: poor sleeping conditions in dorm life. The issue arose when one member’s friend started experiencing difficulty sleeping upon moving into his shared dorm. We asked ourselves, “How can we help this friend?" Here’s an idea, make a curtain they can set up in their room that separates their space at night, and don’t just make a curtain, make it a remote-controlled curtain so that they can move the sheet from their beds.

Our Product:

Our goal was to improve sleep quality for college students by providing a 'curtain-like' product that blocked potential distractions that are frequent in a standard dorm. Additionally, we would like it to be minimally invasive, compact, and easy to set up. Its purpose is to section off parts of a room to provide privacy by blocking/ reducing light and noise across the 'curtain-barrier'.

Design Requirements:

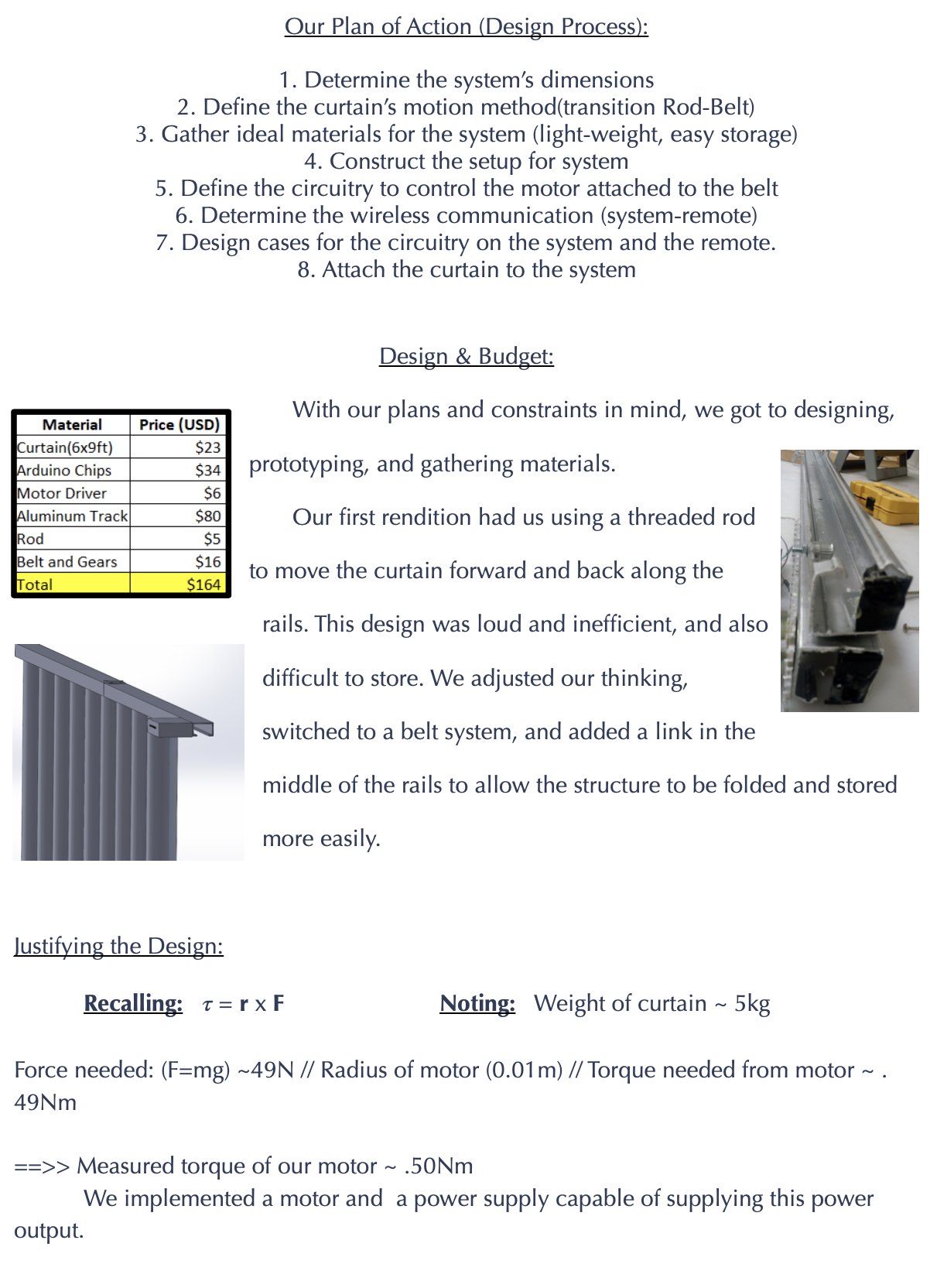

Before starting the design process, we determined what bounds we needed to work within to successfully integrate the proposed system into dorm life. We concluded we needed six square feet of unobstructed space (area) with nine feet of vertical clearance to allow for 2 mounting points on the floor, 2 on the ceiling, and lastly to adhear with CU's school policy regarding fire safety.

Testing:

Our first test was to troubleshoot the circuit itself. Step one in troubleshooting a circuit is to make sure all of your wires are solid. Using a voltmeter and continuity tester, I was tasked with going through and checking each individual wire at each connection point. Re-establishing our repaired section of circuit, I soldered the rest into place and moved on to component testing.

We tested using varying numbers of mounting-holes in our curtain, and came to the conclusion that the fewer holes the better. This was due to more holes creating more points of contact resulting in more friction. We also experimented with different curtain sizes and materials, and chose to go with a lighter curtain so that the motor was not strained in trying to pull the curtain via our belt-drive.

Timeline:

March (11-15): Gathering required materials for the final product, start manufacturing frame-structure

March (18-29): Finish the manufacturing process for the system’s structure

April (1-5): Adjust curtains, to the structure ensuring a manual functioning

April (8-12): Develop accurate coding to ensure the correct movement of the curtains in the system

April (15-18): Work to make moving parts as quiet as possible

April (19-21): Reduce size of remote housing and shrink form factor of any other components if possible

April (22 - 24): Clean up finishes on track/ component parts to make more aesthetically pleasing

April 25: Present the project at Expo

Overview: